Overview

This product is specifically developed to meet the technical requirements of automotive turbochargers. Using fluorosilicone elastomer as the base polymer and a unique compounding process, it provides a specialized fluorosilicone rubber that meets the stringent demands of turbocharger hoses for high/low temperature resistance and excellent fuel resistance.

During production, it can be directly calender-laminated and co-vulcanized with methyl silicone rubber without special treatment, ensuring a simple and efficient process. It is widely applicable to automotive turbocharger hoses and oil-resistant hose components in mechanical equipment.

Product Advantages

Easy processing.

Low compression set.

Good mechanical properties with high strength and resilience.

Excellent adhesion with silicone rubber.

Testing

Curing agent: 2% DCBP (Di(2,4-dichlorobenzoyl) peroxide).

Primary vulcanization (hot air): 180 °C × 30 minutes.

Secondary vulcanization (hot air): 200 °C × 2 hours.

This curing system is suitable for manual or machine-wound hoses. The hose structure typically consists of a single inner layer of fluorosilicone rubber (calendered thickness 0.5–1 mm) and multiple outer layers of fabric-reinforced silicone rubber.

For customers requiring different vulcanization temperatures, the curing system must be adjusted accordingly.

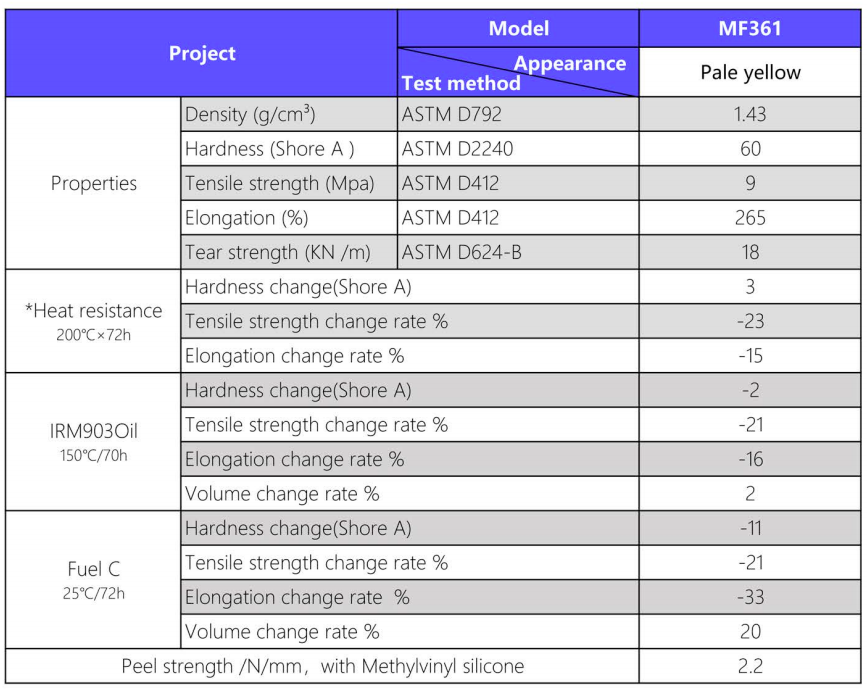

Related Parameters