Description

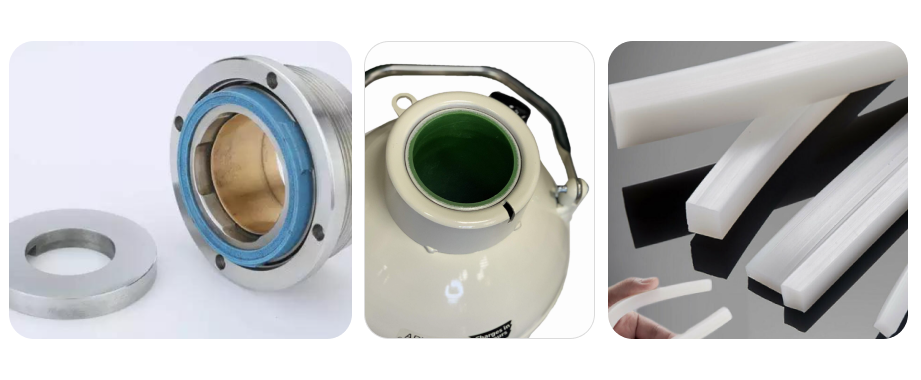

This material can be used for compression molding, injection molding, and extrusion processing of tubes. Through molding or extrusion, it can be processed into various products such as sealing rings, gaskets, tubes, and rods. It is widely applied in electronics, electrical equipment, aerospace, and military fields, particularly in parts requiring low-temperature resistance, radiation resistance, high damping, and ablation resistance.

Product Advantages

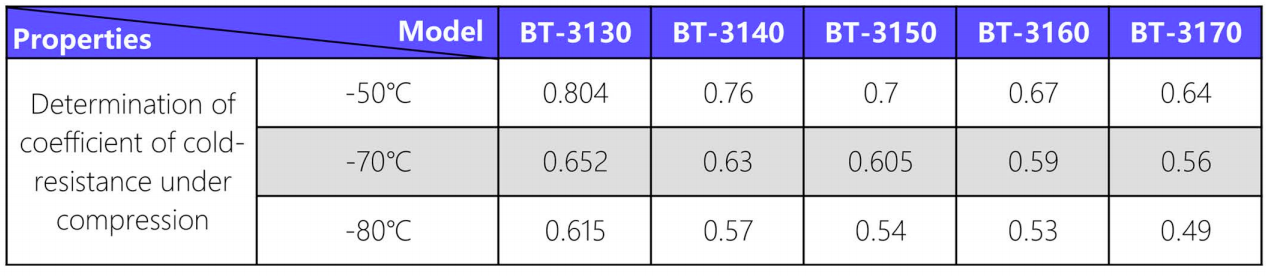

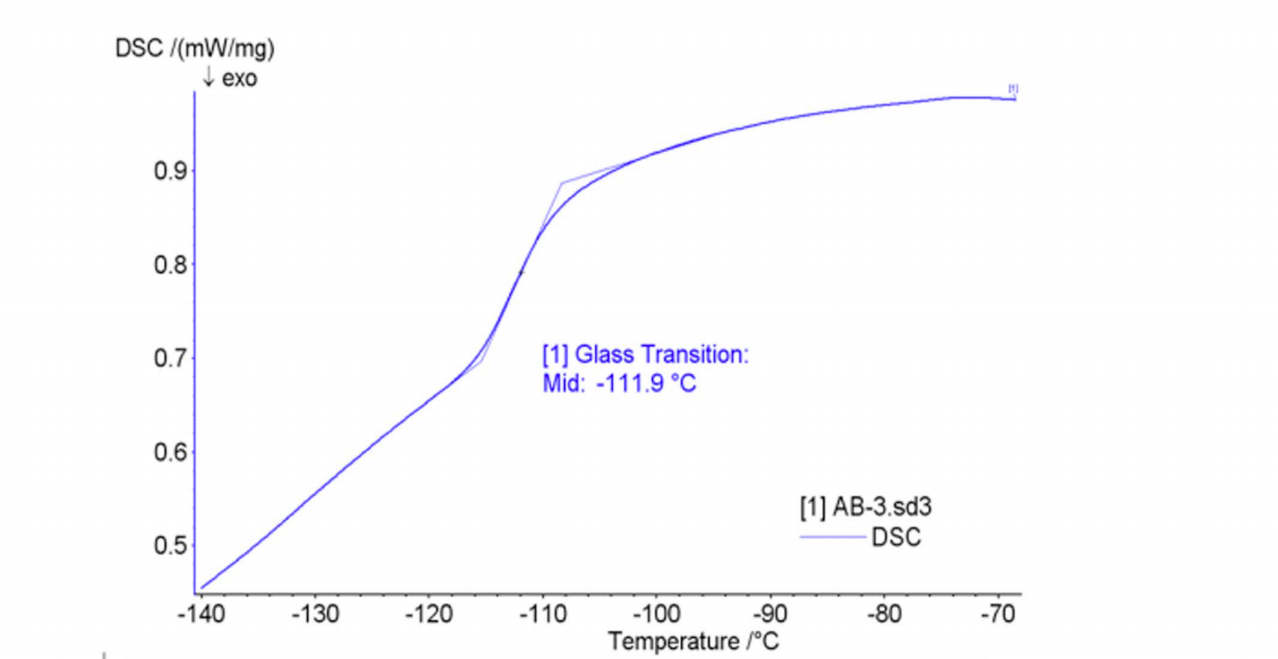

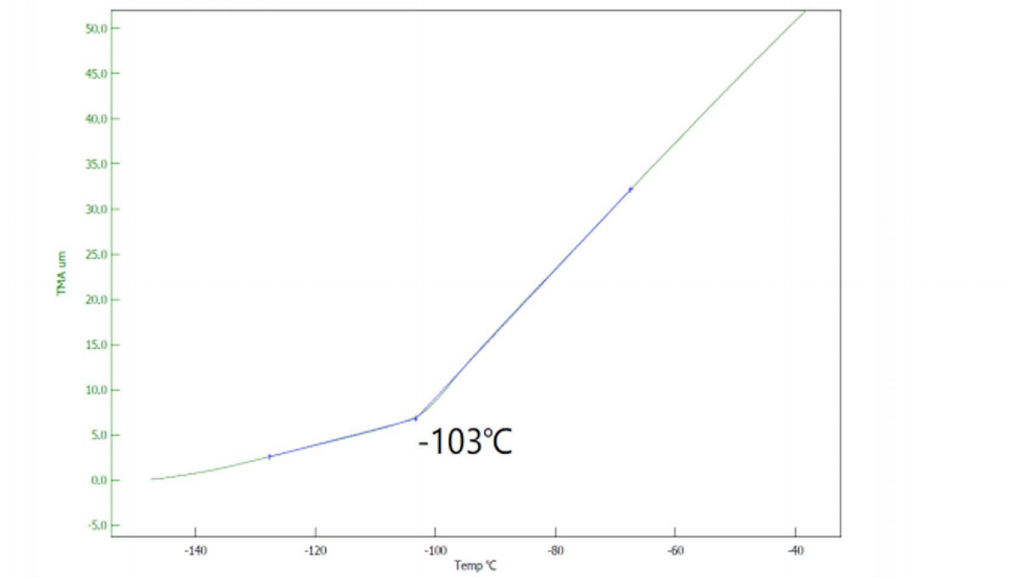

Maintains flexibility at ultra-low temperatures (down to -100 °C).

Excellent performance in ultra-low-temperature environments.

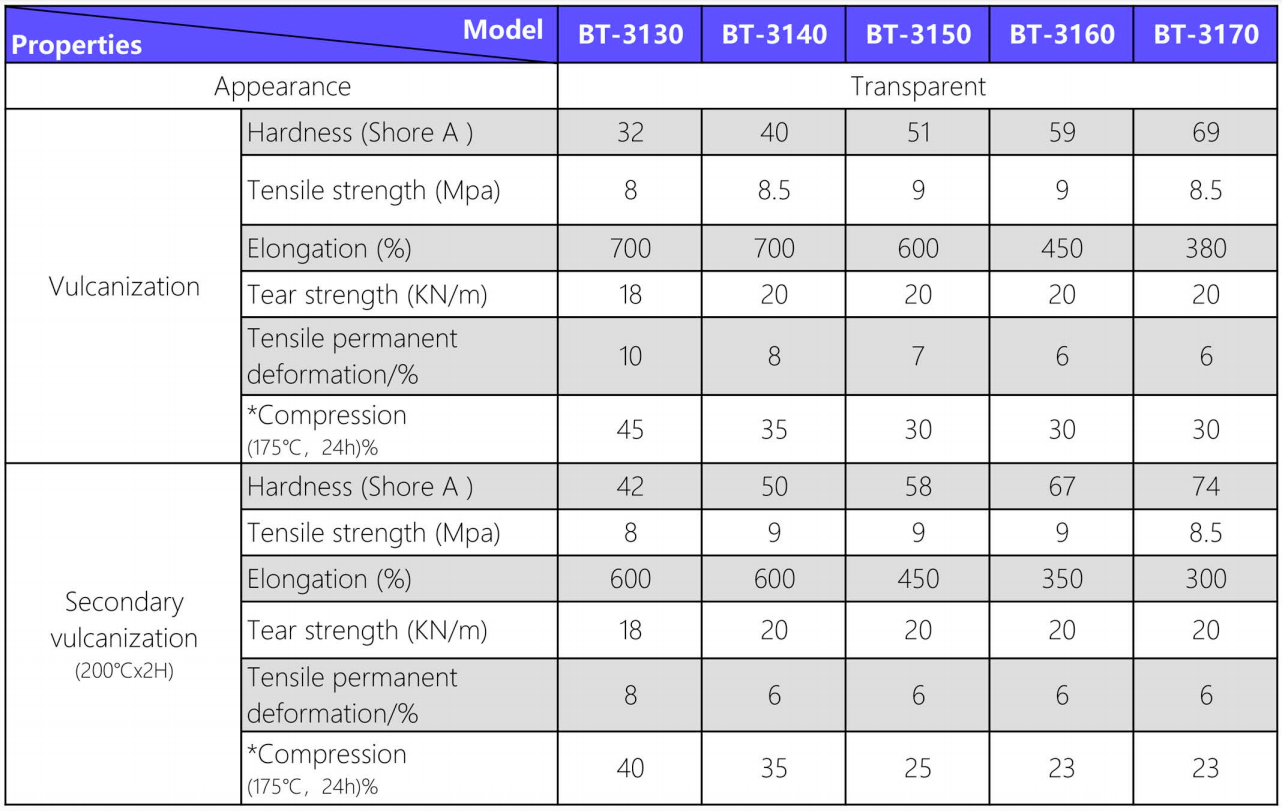

Good physical and mechanical properties.

Reliable damping performance.

Outstanding radiation resistance.

Testing

Additive amount: 1.2% DBPH (2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane, 40% active content).

Curing process: Primary vulcanization at 170 °C × 5 minutes.

Related Parameters