1. Introduction

Y-904-1 is a single-coat, water-based surface treatment agent designed for bonding peroxide-cured elastomers to phosphated steel and other rigid substrates. With good resistance to hot oil, hot water, and other engine oils, Y-904-1 is suitable for manufacturing gaskets, seals, and NVH (Noise, Vibration, and Harshness) components.

2. Features & Advantages

Easy to use – In most applications, only a single coat is needed, reducing labor, storage, and transportation costs.

Environmentally friendly – Dilutable with deionized water and has lower VOC emissions.

Versatile – Facilitates adhesion of various silicone rubbers to many rigid substrates such as phosphated steel, nylon, and aluminum.

High environmental resistance – Exhibits good durability in high-temperature fluid environments; ideal for gaskets and seals.

3. Applicable Materials

Fluoroelastomers (FKM) – Peroxide-cured / AFLAS

Methyl Vinyl Silicone Rubber (VMQ) – Peroxide-cured

Methyl Phenyl Vinyl Silicone Rubber (PVMQ) – Peroxide-cured

Trifluoropropyl Methyl Vinyl Silicone Rubber (FVMQ) – Peroxide-cured

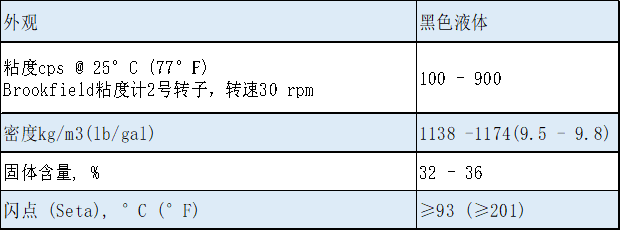

4. Characteristics

Typical data are not to be used as product specifications.

5. Usage Instructions

Surface preparation – Thoroughly clean the metal surface before application. Remove protective oils, cutting oils, and greases using a solvent-based degreaser or alkaline cleaner. Use appropriate chemical or mechanical methods to remove rust, corrosion layers, or oxides; sandblasting is recommended for best results.

Mixing – Stir the adhesive for 10–20 minutes or until uniform in color. Ensure solids from the bottom of the container are fully mixed. Do not shake.

Application – The adhesive can be applied by spraying or dipping. For optimal results, pre-bake the metal parts at 60–65°C (140–150°F) before spraying. The dry film thickness should be 7.6–17.8 µm (0.3–0.7 mil), regardless of the application method.

Drying/Curing – Allow coated parts to air dry for 30–60 minutes. Forced hot-air drying is recommended for thorough drying. The adhesive cures during rubber vulcanization.

Cleaning – Remove cured adhesive with solvents such as acetone, MEK, or alcohol.

6. Shelf Life and Storage

Shelf life is 12 months from the date of shipment, provided the recipient uses the original, unopened containers. Store at 15–35°C and do not refrigerate.