Overview

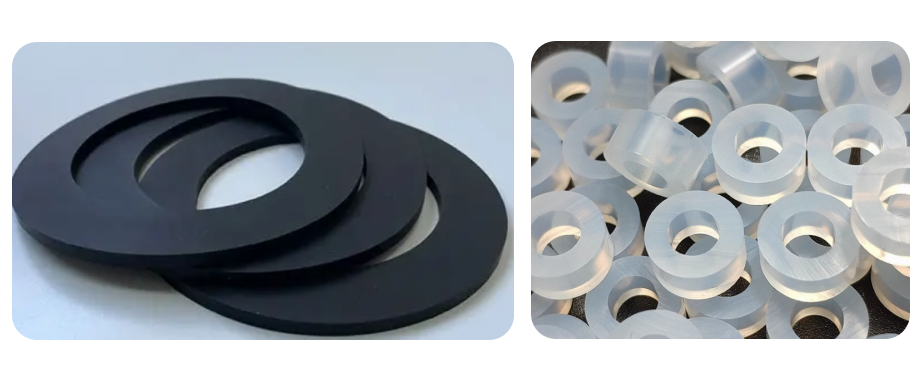

BT-3160M is a methyl phenyl vinyl silicone rubber compound with a medium phenyl content. It is primarily designed for damping and vibration isolation applications, with important uses in the automotive, hydraulic, and aerospace industries. The material provides excellent radiation resistance. Based on the same formulation, silicone rubber compounds of different Shore A hardness can be customized. After adding the appropriate curing agent, the material can be vulcanized and molded at high temperature (suitable curing agents include DBPMH, DBPH, and platinum-based curing systems).

Product Advantages

Excellent physical and mechanical properties.

Good damping performance.

Outstanding radiation resistance.

Testing

Additive amount: 1.2% DBPH (2,5-Dimethyl-2,5-di(tert-butylperoxy)hexane, 40% active content).

Curing process: Primary vulcanization at 170 °C × 5 minutes.

Mechanical Properties

Shore A Hardness .................................................... 59

Tensile Strength (MPa) ............................................ 8.5

Elongation at Break (%) .......................................... 400

Tear Strength (kN/m) .............................................. 28

Permanent Tensile Set (%) ...................................... 6

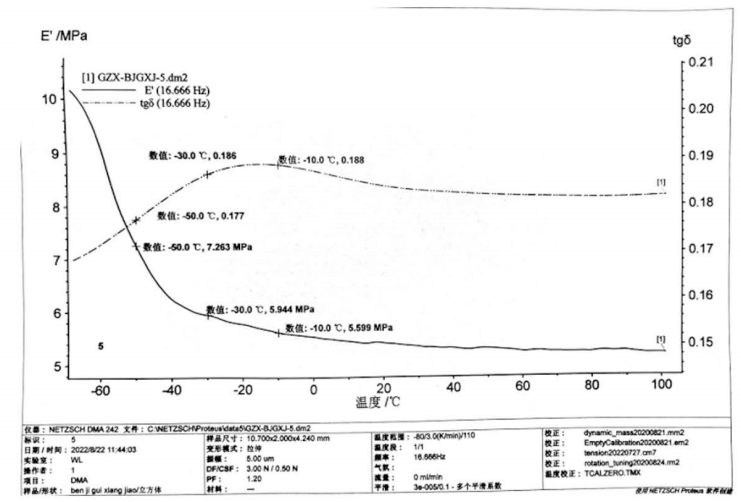

Damping Properties

Medium-phenyl-content silicone rubber (other phenyl content levels can be customized) exhibits inherent damping performance, generally reflected in damping factor values. The damping factor is influenced by hardness, test amplitude, frequency, crosslinking density, temperature, and temperature variation rate. The chart above provides reference data for this product. Damping performance can be tailored according to customer requirements.