Overview

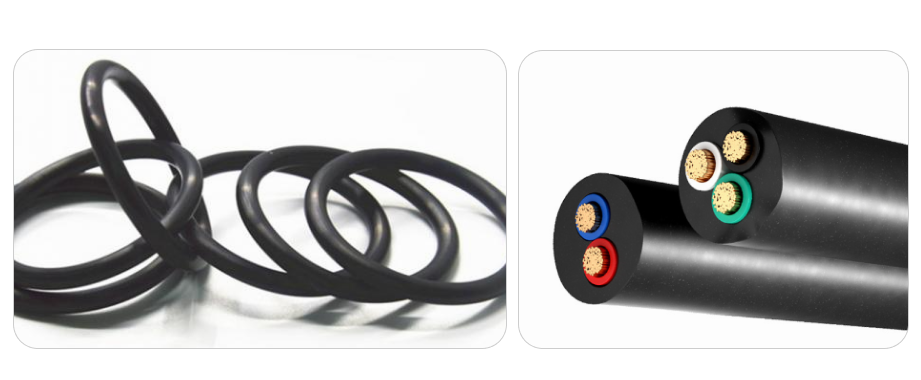

This material can be processed by compression molding, injection molding, and extrusion into various products. After molding or extrusion, it can be fabricated into seals, gaskets, tubes, and rods for applications in electronics, aerospace, aviation, and defense industries, where resistance to high temperatures, radiation, and ablation is required.

Product Advantages

Excellent ablation resistance at temperatures above 350 °C.

Maintains good physical properties under high-radiation conditions.

Exhibits strong mechanical performance with high tensile strength and elasticity.

Testing

Additive dosage: 2–2.5% Bis(2,5-dimethyl-2,5-di-tert-butylperoxy)hexane (40% active content).

Process: Compression molding at 170 °C × 5 min.

Radiation Resistance

The radiation resistance is influenced by both the phenyl content in the main chain and in the side groups, as well as the proportion of methyl groups, which affect the overall properties of the compound.

Excellent resistance to radiation: under a gamma irradiation dose of 1024 kGy, the vulcanizate retains tensile strength greater than 7 MPa and elongation at break over 200%.