Overview

Methyl phenyl silicone gum contains a large number of phenyl groups in its molecular structure. In addition to the general high-temperature resistance and dielectric properties of methyl vinyl silicone rubber, it also exhibits superior radiation resistance, ablation resistance, mechanical properties, and excellent low-temperature performance. This product is insoluble in water but soluble in toluene and other solvents. It features low compression set, excellent resistance to saturated steam pressure, and outstanding thermal stability.

Product Advantages

Flexibility retained at ultra-low temperatures down to -110 °C, making it suitable for extreme cold environments.

Long-term storage stability.

Excellent damping properties.

Superior radiation resistance.

High consistency, low volatility, odorless, and outstanding thermal stability.

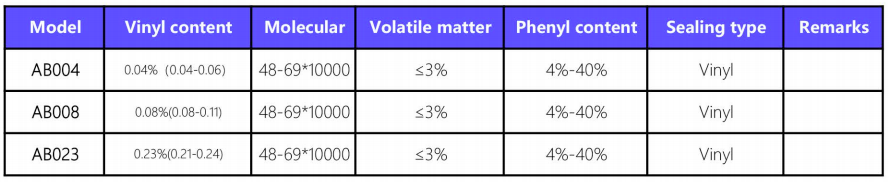

Product Types

Raw Gum Quality

The performance of the final product is directly influenced by the structural type of phenyl silicone gum used. For methyl phenyl vinyl gum, the vinyl content and distribution have a significant impact on the physical and curing properties of the vulcanized rubber. The phenyl content largely determines the low-temperature resistance, damping performance, and radiation resistance of the vulcanizates.Vinyl Content

Increasing the vinyl content in the raw gum raises the crosslinking ratio, which enhances hardness and tensile strength of the vulcanizates, while reducing elongation and compression set.Vinyl Position and Distribution

Vinyl-terminated gums provide better vulcanizate performance than general-purpose non-terminated gums. This is because terminal vinyl groups promote chain extension during crosslinking, thereby improving the mechanical properties of the vulcanizates. Using D4 as the raw material, our gums achieve a more uniform distribution of side-chain vinyl groups, resulting in higher crosslinking density and improved resilience.Phenyl Content

Different levels of phenyl content define the functional performance of phenyl silicone rubber.Low phenyl content: best low-temperature resistance.

Medium phenyl content: significantly improves damping properties.

High phenyl content: greatly enhances radiation resistance.